Optimal Timing for Stamped Concrete

Choosing the right time for stamped concrete service ensures optimal results and durability. Weather conditions, temperature, and humidity significantly influence the curing process and final appearance of stamped concrete installations.

Spring and early fall are generally preferred for stamped concrete projects due to moderate temperatures and lower humidity levels.

Temperatures between 50°F and 85°F are optimal for pouring and curing stamped concrete, preventing issues like cracking or improper setting.

Avoid scheduling during rainy or extremely hot days, as excess moisture or heat can compromise the integrity and appearance of the stamped concrete.

In colder climates, it is best to wait until temperatures consistently stay above freezing to prevent damage from frost.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Popular materials for Stamped Concrete Service and why they hold up over time.

Simple add-ons that improve Stamped Concrete Service without blowing the budget.

High-end options that actually feel worth it for Stamped Concrete Service.

Finishes and colors that play nicely with Stamped Concrete Service.

Little measurements that prevent headaches on Stamped Concrete Service day.

A 60-second routine that keeps Stamped Concrete Service looking new.

A frequent mistake in Stamped Concrete Service and how to dodge it.

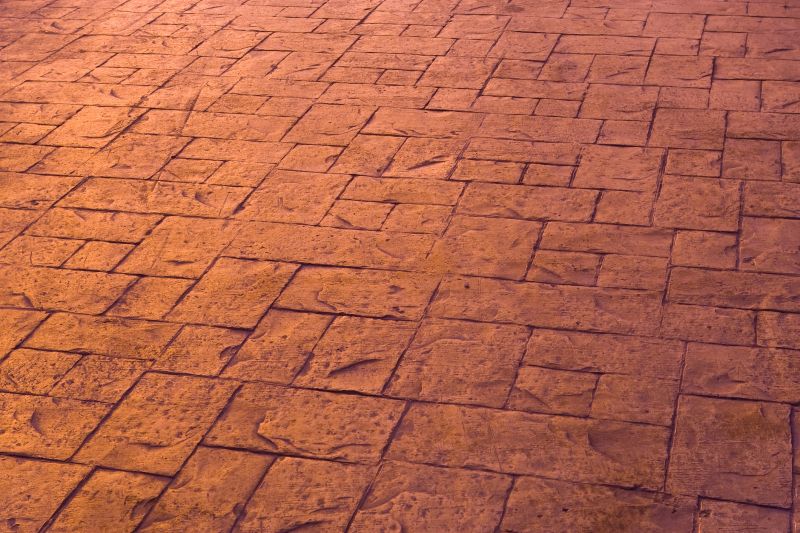

Stamped concrete offers a versatile and durable surface option for various applications, including patios, walkways, and driveways. The process involves imprinting patterns into freshly poured concrete, which can mimic the appearance of stone, brick, or other materials. Proper timing during installation is crucial to achieve the desired aesthetic and longevity. According to industry data, installing stamped concrete during suitable weather conditions reduces the likelihood of defects and extends the lifespan of the surface.

Statistics indicate that correctly timed stamped concrete installations can last for decades with minimal maintenance. Temperature and weather conditions during installation directly impact the curing process, affecting color consistency and pattern clarity. Proper scheduling ensures the concrete cures evenly and reduces the risk of cracking or surface imperfections.

Small tweaks to make Stamped Concrete Service safer and easier to use.

Lower-waste or water-saving choices for Stamped Concrete Service.

The short, realistic tool list for quality Stamped Concrete Service.

Rough timing from prep to clean-up for Stamped Concrete Service.

Quick checks and paperwork to keep after Stamped Concrete Service.

Examples that show the impact a good Stamped Concrete Service can make.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Ways to make Stamped Concrete Service work in tight or awkward layouts.

Interested parties are encouraged to contact for more information about scheduling stamped concrete service at the optimal time. Proper planning ensures the best results and longevity for the surface.